In the extreme conditions of deep-sea operations, the power systems of nuclear submarines face significant challenges: high-power loads, limited heat dissipation space, extreme temperature and pressure conditions, and a strict requirement for absolute reliability. As a high-tech enterprise focused on the research and production of high-power resistors, we have developed **customized water-cooled resistor modules** specifically for the unique needs of nuclear submarines. These modules feature a dual-side water-cooling substrate heat dissipation technology, combined with a 10KV voltage rating and the excellent performance of nickel-chromium alloy resistor elements, providing efficient, stable, and safe power load solutions for deep-sea equipment.

1. Customized Design: Precisely Matching the Complex Conditions of Nuclear Submarines**

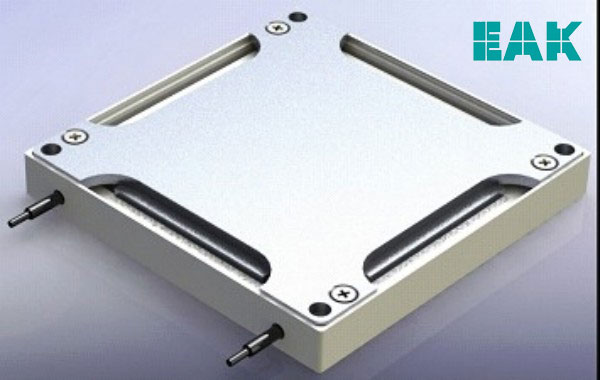

The power systems of nuclear submarines must operate at high power density in confined spaces, while traditional air-cooled or single-water-cooled resistors struggle to meet the dual demands of heat dissipation efficiency and spatial utilization. Our customized water-cooled resistor modules achieve precise adaptation through the following technologies:

Dual-Side Water-Cooling Substrate Structure: Utilizing an up-and-down dual-channel water-cooling design, the coolant flows around both sides of the resistor element, increasing the heat exchange area by over 60%. This ensures that the temperature rise remains below 45℃ at 3.6KW power, significantly exceeding industry standards.

Modular Combination Solutions: Support for flexible configurations of multiple resistor elements in parallel and series, allowing adjustments in module size and interface location according to submarine cabin layouts for seamless integration with power systems and propulsion devices.

10KV Insulation Protection: Achieved through ceramic filling and epoxy resin encapsulation processes, providing high-voltage insulation and arc resistance within a compact volume, meeting the extreme safety requirements of nuclear submarine power systems.

2. Technological Breakthroughs: Synergy Optimization of Nickel-Chromium Alloy and Thermal Management

Nuclear submarines operate for extended periods in high-humidity and high-salinity environments, demanding stringent corrosion resistance and long-term stability from resistors. We have selected nickel-chromium alloy resistor elements as the core conductive material due to their advantages:

1. Low Temperature Coefficient (TCR): Resistor value variations of less than ±5ppm/℃ in the -50℃ to 200℃ range, ensuring precise power output.

2. Resistance to Sulfidation and Oxidation: Surface passivation treatment technology can withstand corrosion from sulfides in the deep-sea environment, with a design life exceeding 100,000 hours.

3. High Power Density Capability: The high melting point (1455℃) and excellent thermal conductivity of nickel-chromium alloy allow the dual-side water-cooling structure to achieve a power density 2.5 times that of traditional products.

3. Application Scenarios: Comprehensive Support from Experimental Simulation to Tactical Deployment

Our customized water-cooled resistors have been successfully applied in several key national nuclear submarine projects, covering the following critical scenarios:

Propulsion System Load Testing: Simulating the power requirements of the propeller motor at various speeds, the water-cooled module rapidly absorbs instantaneous overload energy to prevent system fluctuations.

Emergency Power Dissipation: During an emergency shutdown of the nuclear reactor, the resistor can serve as a high-power dissipation load, absorbing and dissipating over 80MJ of energy within 5 seconds to ensure circuit safety.

Electromagnetic Compatibility (EMC) Optimization: By utilizing a distributed layout of resistor elements and a water-cooling shielding design, electromagnetic interference is reduced, meeting the low-noise requirements of submarine communication and navigation systems.

Post time: Mar-31-2025